CUmulative SUM (CUSUM) chart

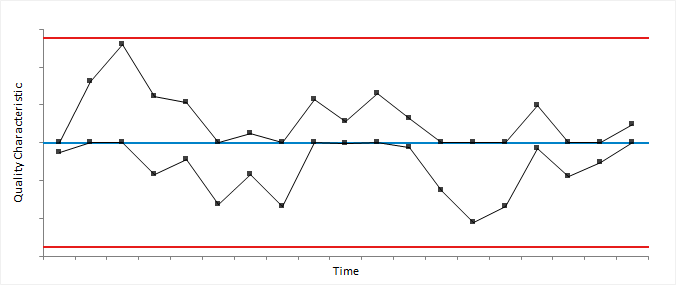

A cumulative sum (CUSUM) chart is a type of control chart used to monitor small shifts in the process mean. It uses the cumulative sum of deviations from a target.

The CUSUM chart plots the cumulative sum of deviations from the target for individual measurements or subgroup means.

The CUSUM requires two parameters:

- A reference value (k) specified in sigma units. k is often set to half the shift to be detected, in sigma units. Default k=0.5 which is equal to detecting a shift of 1 sigma.

- The decision limit (h) specified in sigma units. Default h=5.

It is possible to modify the CUSUM, so it responds more quickly to detect a process that is out-of-control at start-up. This modification is done using an initial CUSUM equal to half of the h parameter.

Like the EWMA, CUSUM is sensitive to small shifts in the process mean but does not match the ability of a Shewhart chart to detect larger shifts. For this reason, it is sometimes used together with a Shewhart chart (Montgomery 2012).

Related concepts

Related tasks